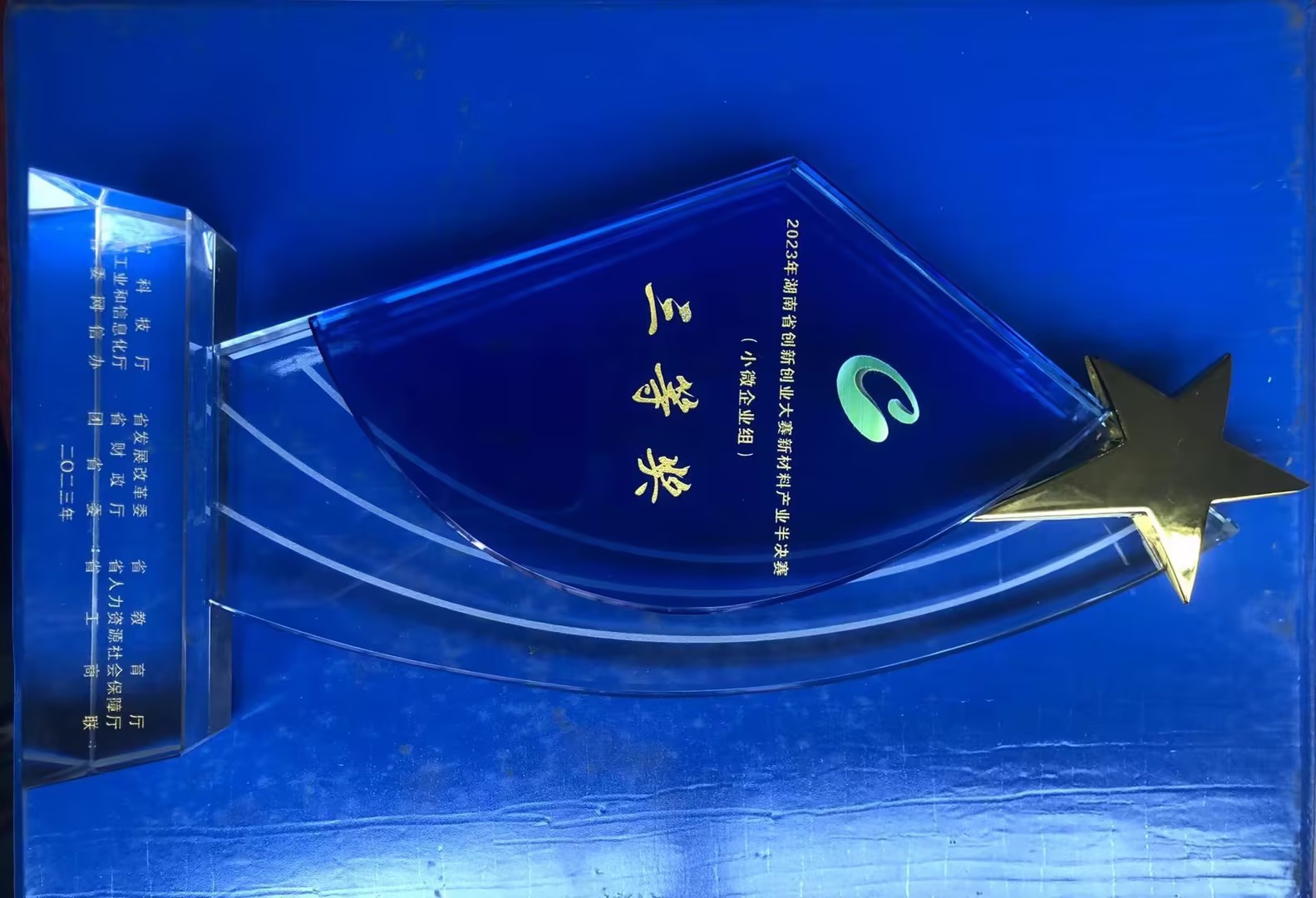

Our team won the third prize in the Innovation and Entrepreneurship Competition

Release time:

2023-08-28

source:

Recently, in the fierce competition of innovation and entrepreneurship competition, our team (Hunan Hongcheng New Materials Technology Co., Ltd.) won the third prize and won honors for our company. This competition is hosted by the Department of Science and Technology of Hunan Province and has attracted outstanding entrepreneurial teams from all over the province to participate.

Our company quickly attracted the attention of the judges with its unique innovation concept and entrepreneurial projects. This idea has attracted much attention in the competition and received unanimous recognition from the audience.

We are in a new era of great technological development and great changes in the century. Grasping and timely applying the latest scientific and technological advancements and adapting to global development trends is a strategic choice for enterprise transformation and upgrading, as well as a "vent" for enterprise development and innovation breakthroughs. Tantalum powder/niobium powder is mainly used in sputtering target materials, high-temperature alloys, special welding, 3D printing, and nuclear industry. With the progress of science and technology, various industries have put forward higher requirements for raw materials, with the most obvious manifestation being the purity of raw materials. In recent years, with the localization process of high-tech, the oxygen content of tantalum powder and niobium powder has been listed as a key concern indicator in the above-mentioned industries.

The 2nd chip, 14th ITO target, and 16th aviation steel, as well as tantalum niobium, are closely related to the 35th bottleneck list approved by the Ministry of Industry and Information Technology of the Chinese Academy of Sciences. Tantalum niobium powder has a broad market in high-end manufacturing.

The company independently develops and breaks through the controllable hydrogen pressure program in the hydrogenation process; The independently developed passivation equipment has achieved precise passivation process with pure oxygen and reactive gas in any ratio, time, and temperature; And adopting advanced oxygen reduction technology; Preparation of high-purity and low oxygen tantalum powder/niobium powder through hydrogenation dehydrogenation process. In the future, we strive to become an industry leader in the field of low oxygen tantalum niobium powder segmentation, an invisible champion, and a national level small giant.

The judges gave high praise to this project, believing that it has great potential in market prospects and technological innovation. Winning the third prize is recognition of our team's innovation ability and entrepreneurial potential. Our company will further strengthen innovation and entrepreneurship, and make greater contributions to social and economic development.

latest news